Precision Machined Parts in Michigan

GLE-Precision, Your Domestic Source for Precision Parts

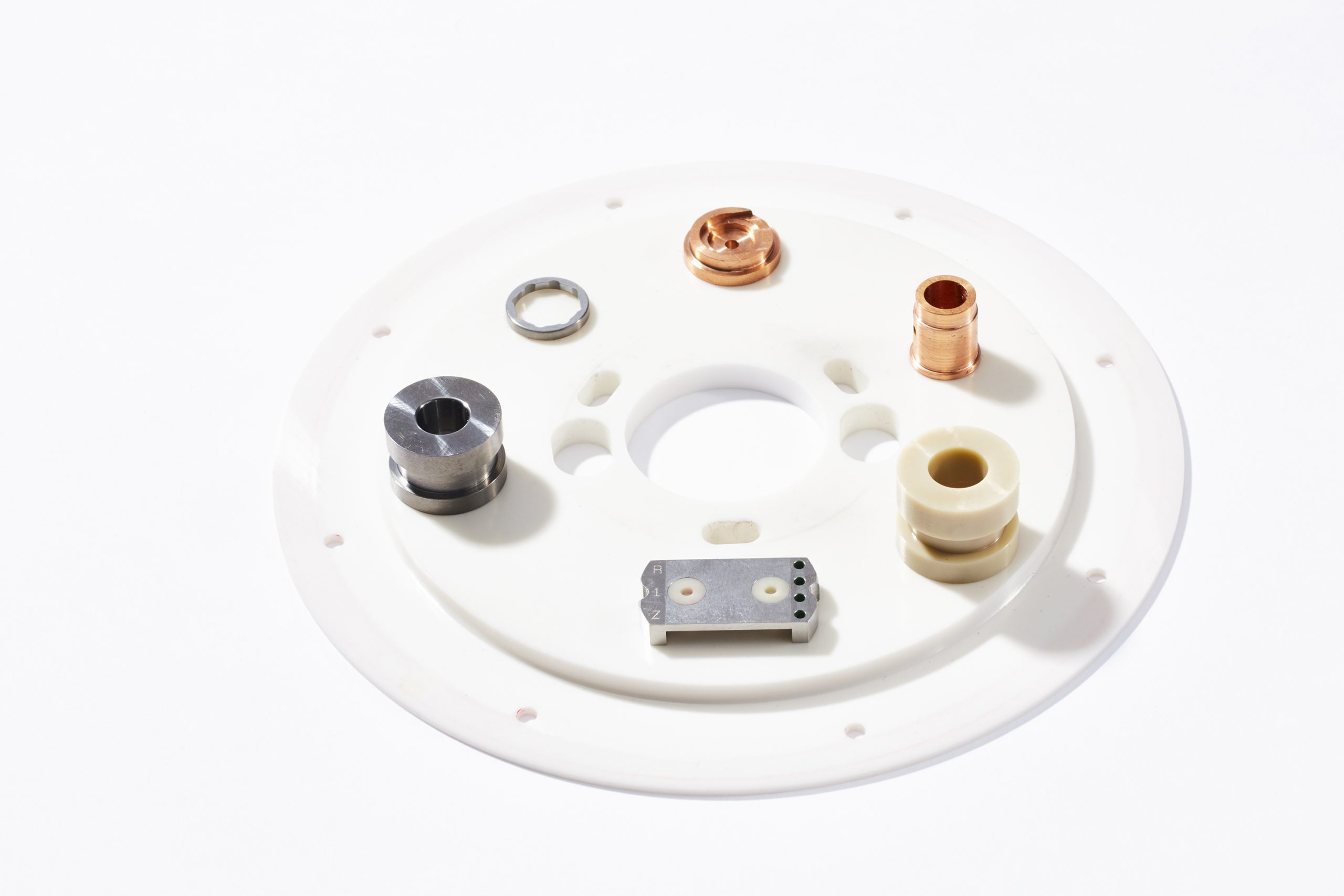

GLE was founded in 1961 and has been producing precision machined parts in Michigan ever since. As such, we have been part of the resurgence of the manufacturing industry. Since the creation of GLE, we have prized ourselves in the manufacturing of precision machined parts. Today, we are an essential supplier for customers in the aerospace, medical, fiber optic, waterjet, semiconductor, and other key industries.

How COVID-19 is Reshaping the Supply Chain

During the COVID-19 pandemic, many manufacturers saw a decrease in availability and an increase in lead times for many products. Because of these delays, manufacturers have restructured their supply chain to incorporate more domestic suppliers. This trend is called reshoring, and GLE General Manager Clint Bucholz was featured in a Middle Market Growth article and spoke on it during the ACG Fall Summit this year.

Automation has helped the U.S. become more competitive with overseas manufacturing. However, raw material prices still favor overseas markets. In the niche market of extreme precision parts manufacturing, operator skill is more important than automation. There is no machine that can manufacture XXX plug or ring gages. Therefore, the ultra-precision market tends to favor the most skilled workers, many of whom are in the U.S.

How Domestic Manufacturing Survived COVID-19

If the COVID-19 pandemic caused problems for supply chains relying on offshore manufacturing, why didn’t it affect the domestic supply chain as well? It did, but there were a couple of key differences. The U.S. was able to determine what manufacturing was essential and kept those businesses open. Many factories retooled to produce essential equipment and supplies. This allowed companies to shop domestically instead of waiting for Chinese factories to reopen.

Reshoring has not been solely due to COVID-19. For a few years, production has been slowly moving away from China to other Asian countries and to the United States. Companies that have seen the benefits of a domestic supply chain moved quickly to bring more manufacturing to the U.S. during the pandemic. The risks of offshore manufacturing are eliminated, and as labor costs increase in the Asian market, the U.S. will only become more competitive.

Michigan Precision Parts

Michigan has been a global leader in the automotive industry since Henry Ford pioneered the assembly line in Detroit. Recently, it has become known for its medical and aerospace manufacturing as well as automotive. Through GLE-Precision, precision machined parts from Michigan travel throughout the world for the most precise applications. Along with various gaging and tooling for the automotive industry, GLE produces the central guidance pins for navigation and targeting systems, critical tooling for semiconductor chip manufacturing, coating dies for 5G fiber optic cables, and more.

GLE’s core capabilities are producing tight tolerances, small parts and holes, and high surface finishes. It’s easy for a company to say they produce tight tolerances when in reality they can hold slightly better than standard tolerances. We can hold a tolerance down to .000003″ (.0762µm) – that’s 100x smaller than a human red blood cell! We have produced precision pin gages that are smaller than a human hair, below .002″ OD. And if we could shrink the Earth to 2″ around, we could lap Mount Everest to be the size of the Lincoln Memorial!