GLE-Precision: The Precision Pin Manufacturer

Gages Down To .001” OD

Quality is Key in Manufacturing Precision Pins

What is considered “small” to you? What are your needs and applications for small gage pins? GLE-Precision is a precision pin manufacturer, which means:

At GLE-Precision, our foundational capabilities are:

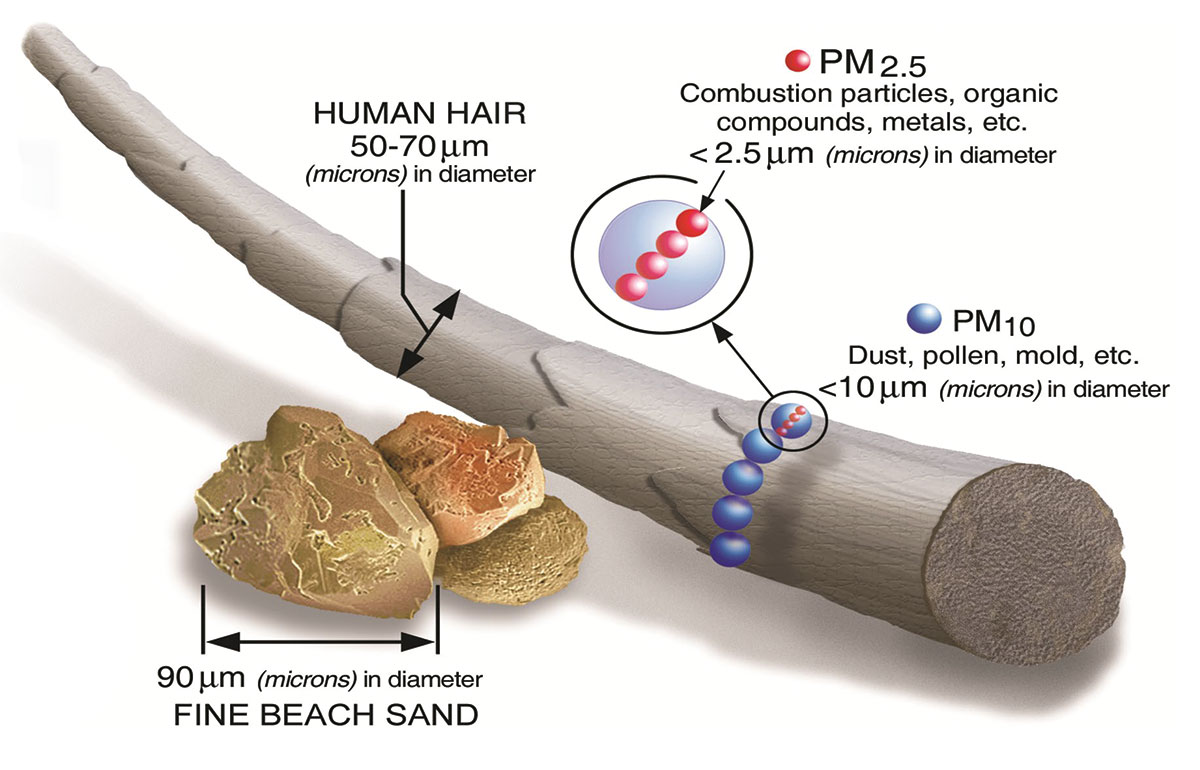

– small parts (ID/OD/OAL: .002” [.0508mm] or less)

– surface lapping (.4RA [.01016 micron] or less)

– precision tolerances (.000003” [.000076mm] or less).

The three foundational capabilities are part of our core and what we do as a company very well. The majority of the parts you will see at GLE-Precision have one of these three core capabilities- either it’s small, it has a high surface finish or it has a precision tolerance.

Precision Pin Manufacturing: Small Parts Today

In recent months, our team has developed a process that is now allowing us to produce class X (+/-.00004” [.001016mm]) tolerance gages with an OD of .002″ (.0508mm). The machinists are not stopping there. They have had success in producing class XX (+/-.00002” [.000508mm]) gages down to .001” (.0254mm) OD and, are seeing encouraging results on gages down to .0008” (.02032mm) OD.

Precision Pin Manufacturer Mailing

If you are a current customer of GLE-Precision, within the last few years you would have received a small vial that looks empty. If you hold the vial up to the light, you will notice it is a pin gage with one end painted yellow. We had several customers call and ask why we sent them an empty vial. After telling the customer they needed to hold the vial up to the light to see the gage inside, they were shocked at what they saw. This is the precision that we pride ourselves on. This is precision beyond belief.

Applications for Precision Pin Manufacturing

There are many applications for these small gages in the medical and inspection markets. In the medical world, small, precision pins are used to inspect the hole size of suture needles. GLE-Precision manufacturers the precision pins to check the hole size, along with the suture tooling used by the needle manufacturers. Common sizes ordered are .008″ (.2032mm) and smaller. For inspection, small pins are used as probes and also as a checking device to inspect a hole or a depth. We have customer who request these precision pins in steels, carbides and sometimes ceramics. The OD size we can get down to, very much depends on the material we are using. Contact our Sales Team to see if we can manufacture the precision pins you need for your application!

Precision Pin Applications

PRECISION PIN MANUFACTURING: MEDICAL

Checking small diameters of surgical or suture needles

PRECISION PIN MANUFACTURING: INSPECTION

Inspecting small diameters in componentry and tooling.