Carbide Gaging

EXPEDITE OPTIONS AVAILABLE

Carbide Gaging and Masters

GLE-Precision manufactures gages and masters to A.G.D. standard dimensions in tolerance classes XXX, XX, X, Y, and Z. Standard configurations of gaging products includes Reversible, TaperLock, Tri-Lock, and Inserted Ring; GLE also manufactures special steel, ceramic and carbide gages and masters to customers’ prints.

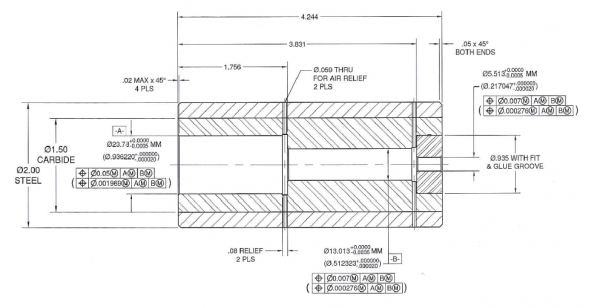

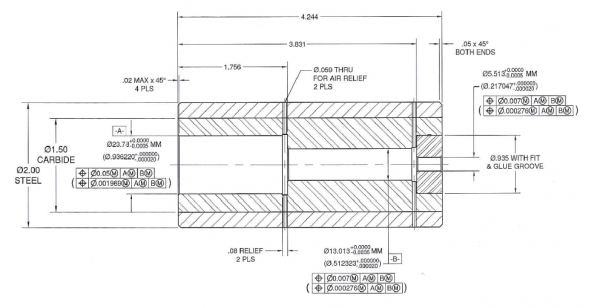

Special Carbide Gaging

Some examples of special gages and masters include true position (concentricity) plugs and rings, gage elements, flat gages, paddle gages, ammunition gages, twin ring gages, master setting discs and rings, gage pins and other precision elements for inspection applications. Send one of our sales team members your prints and we will put together a proposal for your make-to-print gage.

GLE-Precision manufactures carbide gages and masters to A.G.D. standard dimensions in tolerance classes XXX, XX, X, Y, and Z. Standard configurations of gaging products includes Reversible, TaperLock, Tri-Lock, and Inserted Ring; GLE also manufactures special steel, ceramic and carbide gages and masters to customers’ prints.

Special Carbide Gaging

Some examples of special carbide gages and masters include true position (concentricity) plugs and rings, gage elements, flat gages, paddle gages, ammunition gages, twin ring gages, master setting discs and rings, gage pins and other precision elements for inspection applications. Send one of our sales team members your prints and we will put together a proposal for your make-to-print gage.

Plug Gages

Is your application relating to inspecting a hole? GLE manufactures plug gages in sizes from .002″ (.127mm) to 2.511″ (63.78mm), with special applications smaller and larger. Typical plug gage materials include carbide, steel and ceramic. Ceramic, steel and carbide gages and masters can be purchased as Go, Nogo or Master in class X, XX, XXX, Y or Z. Contact us to help determine what material is right for your application.

Ring Gages

Carbide inserted ring gages are manufactured in sizes from .010″ (.254mm) to 4.011″ (101.88mm), with special applications smaller and larger.

The protective outer jackets of larger ring gages, 2.00″ (50.8mm) in diameter and up, previously of steel, are now composed of a special, rigid nylon material that better complements carbide. The gages are lighter in weight and more stable because the new outer jacket, acting as an insulator, resists the transfer of external heat to the carbide gaging element.

Trilock Gages

Do you have a drilled hole you are trying to inspect? Carbide trilock gages are manufacturered to standard dimensions in tolerances classes XXX, XX, X, Y and Z. Sizes range from .725” (18.415mm) to 2.510” (63.75mm), with special applications for larger sizes. GLE-Precision can provide Go, No-go and Master members based on your need.

Master Setting Discs

Master setting discs are available in diameters from .010″ (.254mm) up to 4.011″ (101.88mm) and larger. These are carbide OD gages; tolerances are most commonly applied bilaterally.