TUNGSTEN CARBIDE CORE PINS

INJECTION MOLDING

producing tungsten carbide core pins and inserts on high cavitation molds

Hyperion Precision Solutions has worked closely with most of the world’s top medical product companies for more than a decade to produce tungsten carbide core pins and inserts that are fully validated and incorporated on high cavitation molds.

With maximum tooling rigidity, molders have been able to maximize part quality (CPK) and dimensional repeatability beyond anything previously achieved.

Hyperion Precision Solutions engineers and manufactures high precision, complex form, CraftAlloy™ tungsten carbide core pins, inserts, ejectors, and other injection molding tooling with the exacting level of tolerances and design features that high-precision part molders require.

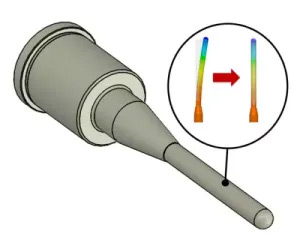

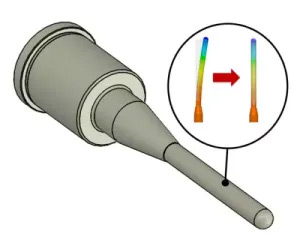

The tooling is harder and more rigid than any other mold tooling material on the market, significantly reducing core shift/deflection, which allows for the highest possible precision and repeatability with injection molded parts.

To further advance this technology, Hyperion Precision Solutions balances the hardness and rigidity of CraftAlloy™ tungsten carbide tooling by incorporating a metallic cobalt binder, which imparts a level of ductility that produces a very robust tooling system.

CraftAlloy™ tungsten carbide tooling is primarily used to produce high precision molded parts, as the material typically allows for higher molding speeds due to its superior heat transfer characteristics.

Rounding out the advances that CraftAlloy™ tungsten carbide material regularly presents to molders is the overall wear life of tungsten carbide tooling. Molders of components molded from Peek and glass-filled type materials have experienced significantly improved wear life of their tooling when migrating from steel and copper alloys to tungsten carbide.

CONTACT US TODAY!

Crafts Technology engineers and manufactures high precision, complex form, CraftAlloy™ tungsten carbide core pins, inserts, ejectors, and other injection molding tooling with the exacting level of tolerances and design features that high-precision part molders require.

The tooling is harder and more rigid than any other mold tooling material on the market, significantly reducing core shift/deflection, which allows for the highest possible precision and repeatability with injection molded parts.

To further advance this technology, Crafts Technology balances the hardness and rigidity of CraftAlloy™ tungsten carbide tooling by incorporating a metallic cobalt binder, which imparts a level of ductility that produces a very robust tooling system.

CraftAlloy™ tungsten carbide tooling is primarily used to produce high precision molded parts, as the material typically allows for higher molding speeds due to its superior heat transfer characteristics.

Rounding out the advances that CraftAlloy™ tungsten carbide material regularly presents to molders is the overall wear life of tungsten carbide tooling. Molders of components molded from Peek and glass-filled type materials have experienced significantly improved wear life of their tooling when migrating from steel and copper alloys to tungsten carbide.

Maximize Repeatability

Optimal repeatability is made possible by the absolute minimization of tooling deflection during the molding process, specifically due to the rigidity of the CraftAlloy™ tungsten carbide core pins. With thermal heat transfer capability similar to beryllium copper, but without its health hazards, tungsten carbide core pins deliver both maximum cooling capabilities and minimal cycle times.

Solve your most challenging mold defects by filling out the form below.