Semiconductor: Wire Bonding Guides

UNMATCHED SKILLS & EXPERIENCE

From an early partnership with major computer manufacturers developing ferrite memory cores to the wire bonding guides used today, GLE offers skill and experience unmatched anywhere in the world.

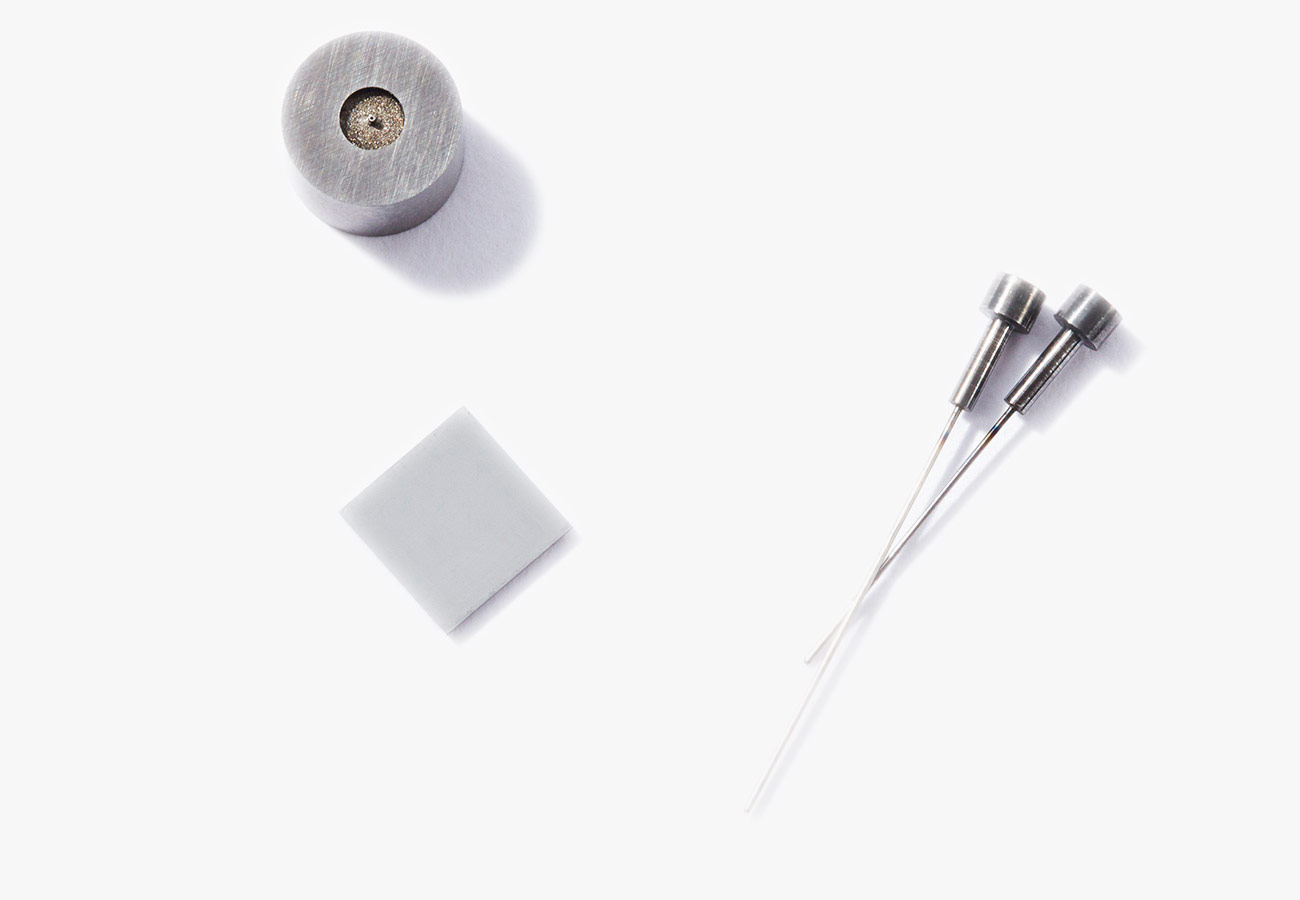

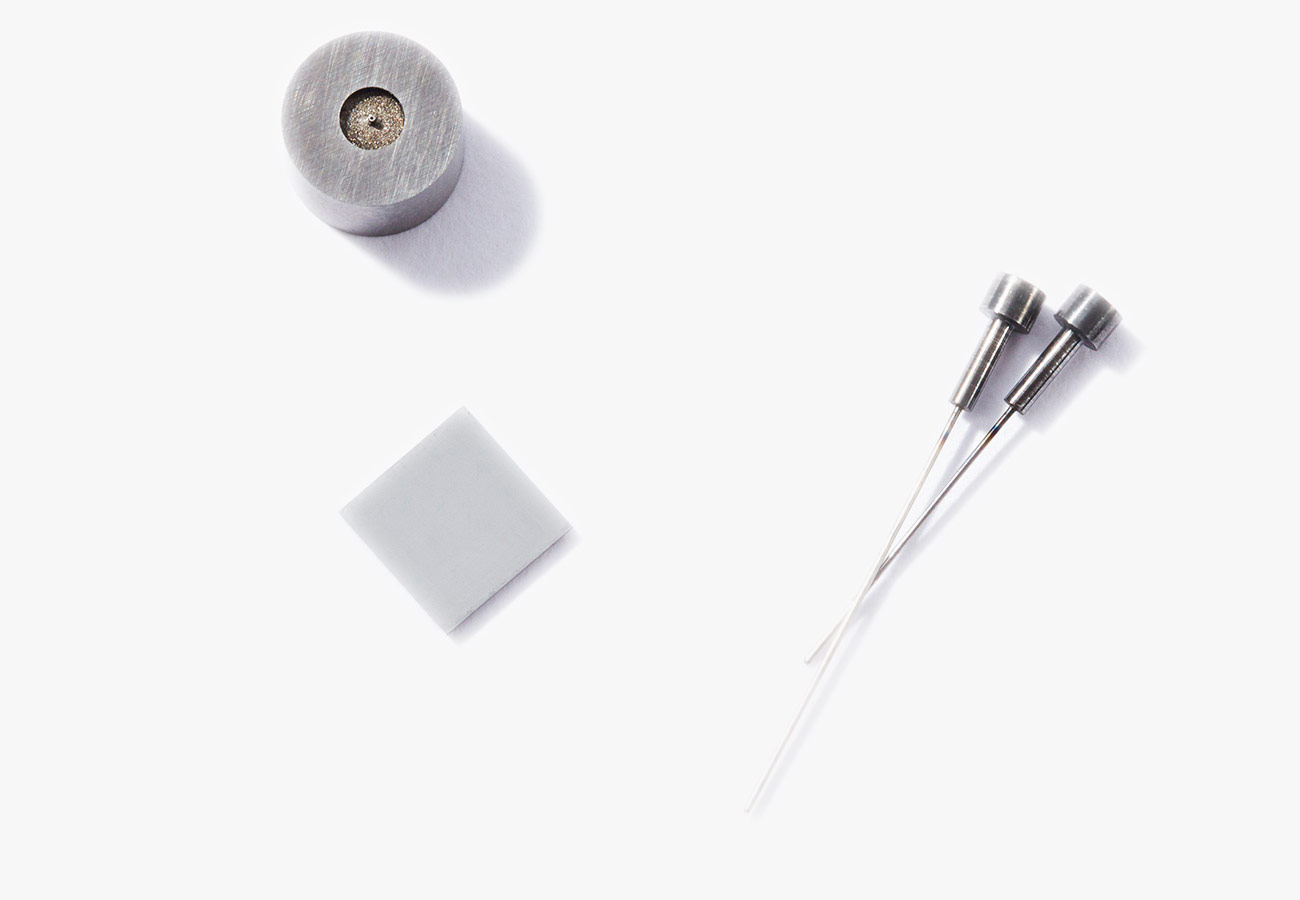

GLE-Precision is a global supplier of tooling and componentry for the semiconductor industry. We have over 50 years’ history of being a major semiconductor manufacturer, specifically supplying the leading semiconductor organizations with wire bonding guides. Our precision machinists manufacturer wire bonding guides and semiconductor parts and components used throughout the chip and technology and semiconductor industries. High finishes (mirror finishes) and flatness are of prime importance for manufacturing the finished product. GLE-Precision has the capability to achieve a .4RA (.01016 micron) finish or better if needed. By conducting a series of proprietary precision lapping services, GLE-Precision machinists are able to meet customer expectations regarding surface finish and flatness. We also have the ability to machine hole sizes to .003″ (.0735mm). Jewel clamps, connectors, gluing and injection nozzles, punches, wire bonding guides and tooling and other components are a few of the parts GLE-Precision has manufactured for the chip and semiconductor industry. Most parts and components are made from carbide, but other materials include hardened steels. We look forward to working with you on your semiconductor project!

What is Wire Bonding and What are Wire Bonding Guides?

Wire bonding involves creating electrical interconnections between an integrated circuit (or other semiconductor device) and silicon chips using bonding wires. Bonding wires are fine wires made from gold and aluminum. The two most common types of wire bonding are ball bonding and aluminum wedge bonding.

Wire Bonding Guides: Two Types of Wire Bonding

Gold wire bonding is achieved through thermosonic bonding. In thermosonic bonding, each end of the wire is melted to form a gold ball, which is the air-free ball. The diameter of the air-free ball is 1.5-2.5 times bigger than the diameter of the wire. Aluminum wedge bonding uses pressure and ultrasonic energy to form the wire bonds. When gold wire is used, temperatures reach 150 degrees Celsius and the process is very similar to gold wire bonding and called thermosonic bonding. Low temperatures are more commonly used when aluminum wedge bonding.

From an early partnership with major computer manufacturers developing ferrite memory cores to the bonding capillary work of today, GLE offers skill and experience unmatched anywhere in the world.

As a global supplier, with over 40 years’ history with major manufactures, GLE manufacturers wire bonding and semiconductor parts and components used throughout the chip industry. High finishes (mirror finishes) and flatness are of prime importance for manufacturing the finished product. Hole sizes to .003. Jewel clamps, connectors, gluing and injection nozzles, punches and tooling are a few of the parts GLE has manufactured for the chip industry.

Wire bonding involves creating interconnections between an integrated circuit or other semiconductor device and its packaging during fabrication