Gage Inspection

QUALITY IS CRUCIAL TO US!

Quality is Key in Gage Inspection

GLE-Precision is a NIST certified gage manufacturer with the capability to perform long form certification and recalibration gage inspections in-house. Inspection equipment and methods for gage inspection are a critical component of GLE-Precision’s day-to-day operations. GLE has a temperature and humidity controlled gage lab equipped with modern and traditional precision dimensional measuring equipment for inspecting gages with the tightest tolerances. With this equipment, GLE is capable of holding accuracies to 0.000003″ (0.00013mm).

Personnel in Gage Inspection

All laboratory personnel are skilled metrologists with decades experience in gage inspection and all inspection equipment and master blocks have precision traceable to the National Institute of Standards and Technology (NIST).

GLE-Precision strives to invest in the most effective inspection equipment needed in today’s precision manufacturing world. We intend to remain on the forefront of the newest cutting edge technology in the gage inspection world.

KEYENCE IM-6225 for Gage Inspection

Inspection equipment and methods are a critical component of GLE-Precision’s day-to-day operations.

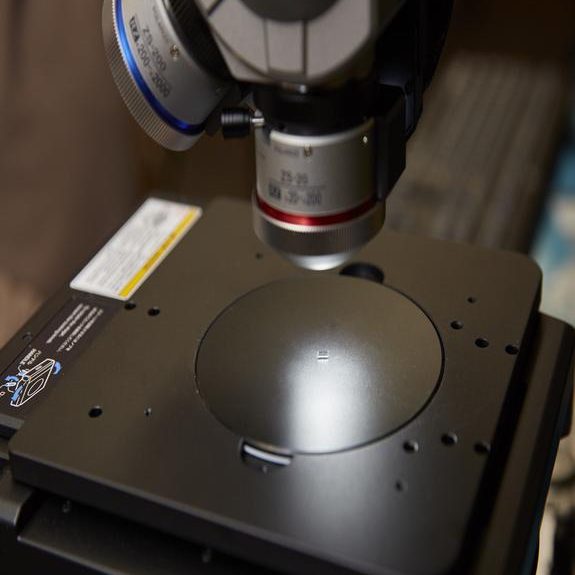

The IMT-6225 is a 2D vision measurement system. This piece of inspection equipment has a measuring capability of +/-.0002″ in wide field mode and .000080″ in high precision mode. Its’ repeatability is to 1um in wide field mode. Repeatability is .5um in high precision mode. Wide field mode allows us to measure anything in a 4″x 8″ area. High precision mode allows us to measure in a 1″ x 4″ field. With incredible speed, the IM can measure up to 99 dimensions within seconds and 3 seconds. With the multi-part function it allows us to measure entire batches in a few minutes versus a few hours.

About the Gage Inspection Equipment

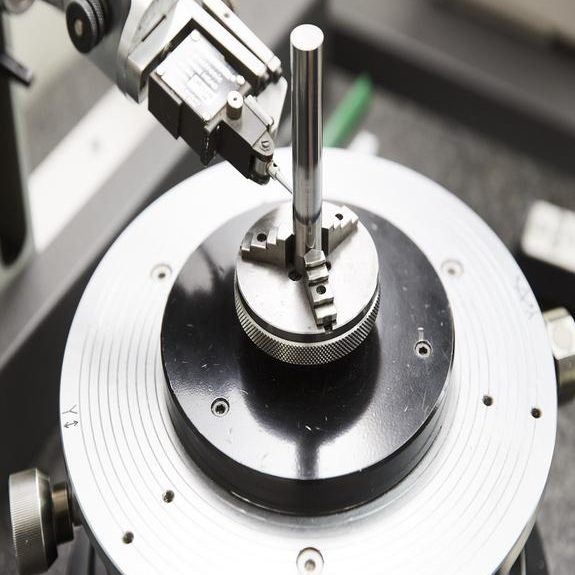

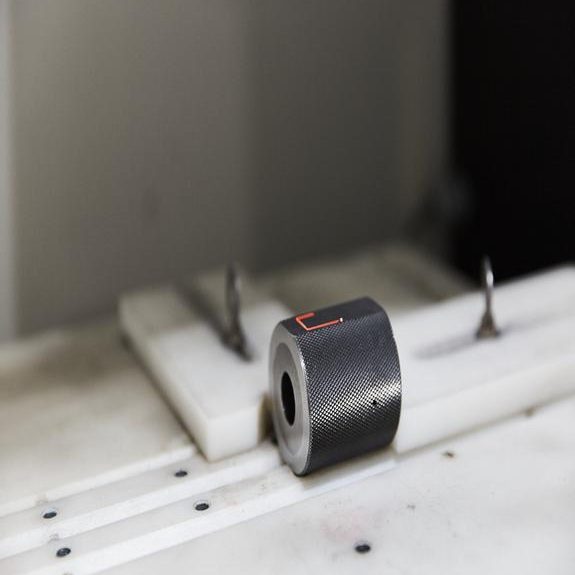

Accuracy of measurement depends upon what is being measured. The Zeiss Rondcom Nex 200 RONDCOM NEX 200 is a universal form tester for the analysis of roundness, roughness and cylinder form. Perpendicularity, parallelism, straightness, flatness, coaxially, concentricity, and thickness error are also analyzed with the RONDCOM NEXT 200.

With rotational error of just 20 nanometers, testers are ideal for a wide range of precision parts that have a height of 200 mm and weigh up to 60 kg. When describing the RONDCOM formtester, the heart of every model is the rotary table on air bearings. Benefits of air bearings compared to a rotary table with mechanical bearings include the following:

• High rigidity and long-term stability

• Non-contact travel, therefore drive vibrations do not affect the results

• No wear and tear

• No lubrication required

• High measuring speeds

• Maximum possible rotation accuracies of up to 10 nanometers