Manufacturing Catheter Parts

What is a Catheter?

A catheter is a thin tube that is often manufactured from a soft plastic material that can be inserted into a body. Catheters are medical devices that medical doctors prescribe. Doctors prescribe them for a few different reasons, but most people think of urinary catheters first. However, intravenous (IV) catheters are generally more important. Doctors insert IV catheters into veins and arteries to inject medication, perform surgeries, and more. Urinary catheterization is the process of using a urinary catheter to drain the urinary bladder when it cannot be emptied normally. Hospital staff will perform this process, typically after surgery. Individuals who have a dysfunctional bladder also use a catheter as a daily habit.

What are the Different Types of Urinary Catheters?

There are three main types of urinary catheters: straight intermittent catheters, hydrophilic catheters, and closed system catheters. Individuals with bladder control issues use straight intermittent catheterization to empty the bladder. This involves self-catheterization and will happen several times a day. Hydrophilic catheters have a polymer coating that bonds to the catheter. The coating reduces friction, reducing the risk of urethral damage. It has been suggested that hydrophilic catheters are less likely to cause infection because they do not require manual lubrication. Finally, closed system catheters are self-lubricating housed within their own collection bag. The sterile collection bag eliminates the need to void the urine into a receptacle. These types of catheters are most convenient for traveling.

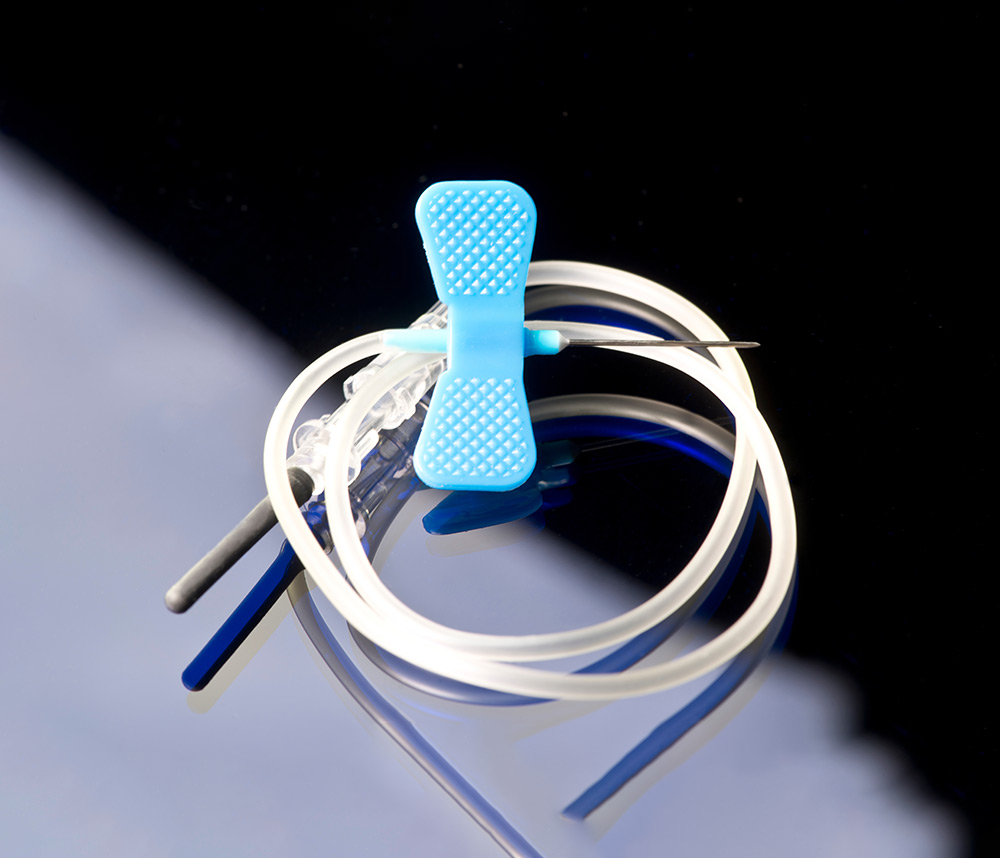

Manufacturing Parts of a Catheter

A catheter system can consist of several different parts. The collection bag, drainage port, and tubes are all important parts of the urinary catheter system. The first step in manufacturing a urinary catheter is the production of the long tube that is inserted into the bladder. To make this tube, manufacturers pour liquid silicone rubber into a rubber mold. The mold is shaped like a catheter with two or three outlets. Then, a tip forming die shapes the tip, and in IV catheters a machine drills holes in the side. The internal configuration of the carbide dies varies for each type of catheter the manufacturer produces. GLE Precision manufactures the carbide dies which various catheter manufacturers use to form the catheter tips.

Challenges in Catheter Manufacturing

Any medical device does not have much room for error, so catheters must be manufactured very precisely. This means that the molds and dies that produce them need very tight tolerances. This can be a challenge, but some companies like GLE have decades of experience in manufacturing with tight tolerances. GLE is able to manufacture catheter parts with tolerances down to .000003″ (.0762µm) and features as small as .002″ (.0508mm). Due to the volume of catheters that manufacturers produce, molds and dies can wear quickly. One way to decrease wear is to polish the contacted surfaces. A lower surface finish value can increase the life of a die by decreasing friction. GLE is able to polish parts as smooth as 0.4 Ra µin (.0106µm). Don’t hesitate to contact us if you are looking for better performance and life out of your catheter dies!